-

Max. Machining Diameter

STANDARD

Ø38mm (1-1/2in)

NON-GUIDE BUSH TYPE

Ø42mm (1-21/32in) -

Max. Headstock Stroke

STANDARD

320mm (12-19/32in)

WITH R.G. B. UNIT

288mm(11/32in) : OP

NON-GUIDE BUSH TYPE

Bar diameter x 2.5 (Max. 95mm) (Max. 3-47/64in) : OP -

Tool

5 tools on the front + 2 tools on the rear + 3 tools on the front : OP

-

5-Spindle Sleeve Holder

NUMBER OF TOOLS

Front 5 tools

Rear 5 tools

MAX. DRILLING CAPABILITY

Ø23mm (29/32 in)

MAX. TAPPING CAPABILITY

M16 x P2.0 -

Power Driven Att.

NUMBER OF TOOLS

Cross Milling: 3 tools

Cartridge Type: at 1 position

MAX. DRILLING CAPABILITY

Ø10mm (25/64in)

MAX. TAPPING CAPABILITY

M8 x P1.25

SPINDLE SPEED

Max 6,000min-1

Drive Motor

2.2kW (continuous) / 3.0kW (5min./30%ED) -

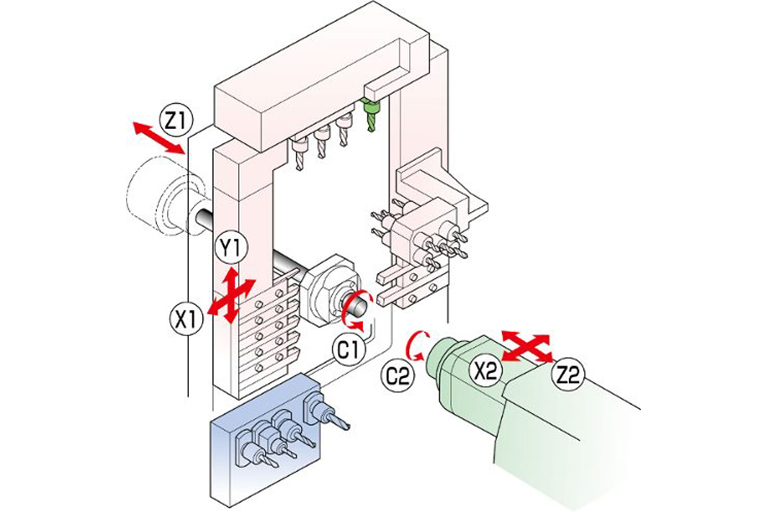

Rapid Feed Rate

36m/min(X1, Y1, Z1, X2, Z2)

-

Main Spindle Indexing Angle

C-axis control

-

Main Spindle Speed

Max. 7,000min-1

-

Main Spindle Motor

7.5kw (continuous) / 11kw (10min./25%ED)

-

Coolant Tank Capability

253ℓ (359ℓ : OP)

-

Dimensions (Width x Depth x Height)

2,740 x 1,315 x 2,120mm

-

Weight

4,250kg

-

Power Consumption

12.8 kVA

- Standard Machine Specifications

- Backworking Attachment Specifications

- Standard Accessories and Functions

- Optional Accessories and Functions

-

Max. Chucking Diameter

Ø38mm (1-1/2 in)

-

Max. Length For Front Ejection

150mm (5-7/8in)

-

Max. Parts Projection Length

70mm (2-3/4in)

-

Back 4-Spindle Unit

NUMBER OF TOOLS

4 tools

MAX. DRILLING CAPACITY

Stationary Tool

Ø14mm (35/64in)

Power-Driven Tool

8mm (5/16in)

MAX. TAPPING CAPACITY

Stationary Tool

M12 x P1.75

Power-Driven Tool

M6 x P1.0 -

Power-Driven Att. Drive Motor

1.0kW (continuous) / 1.2kW (5min./30%ED)

-

Sub Spindle Indexing Angle

C-axis control

-

Sub Spindle Speed

Max. 7,000min-1

-

Sub Spindle Motor

3.7kW (continuous) / 5.5kW (10min./40%ED)

- CNC unit Fanuc 0i-TF

- Operation Panel 10.4 inch color LCD Display

- Manual pulse generator

- Pneumatic unit

- Hydraulic unit

- Automatic centralized lubrication unit

- Coolant level detector

- Door interlock system

- Broken cutoff tool detector

- Drive unit for revolving guide bush

- Revolving guide bush unit

- Air purge unit for revolving guide bush

- Main/Sub collet

- Spindle clamp unit (main/sub)

- 5-Station tool holder (16/20mm)

- 2-Station tool holder (16mm)

- 5-Spindle sleeve holder

- Drive unit for power-driven (gang type tool post: including 3 cross milling tools)

- C's contouring control (main/sub)

- Spindle cooling unit

- Air purge unit for sub spindle

- Back 4-spindle unit

- Work light

- Leakage breaker

- Coolant flow detector

- Parts ejection detector

- Water removal unit

- Oil mist filter

- Beacon

- Chip conveyor

- Rotary magic guide bush unit

- For pneumatic unit rotary magic guide bush

- Non-guide bush type

- Main spindle inner tube

- Parts ejector (Air cylinder type)

- Parts ejector (Spring type)

- Parts ejector with guide tube

- Parts stopper unit

- Parts conveyor

- Drive unit for power-driven B (4-spindle backworking unit)

- Coolant tank large capacity type

- Coolant unit (6.9MPa / 2.5MPa / 0.7 MPa)

- Coolant unit signal cable

- Coolant unit power cable

- Coolant valve (6.9 MPa / 2.5 MPa)

- Coolant pipings

- Coolant cooling unit

- Automatic bar feeder interface

- Compliant with the RS-232C interface

- LAN interface

- Transformer CE marking version

- Transformer CE marking cable

- CE marking version