-

Main Spindle

MAX. MACHINING DIAMETER

Ø51mm (2in.)

MAX. MACHINING LENGTH FOR AUTOMATIC EJECTION

125mm (4-59/64in)

MAIN SPINDLE SPEED

Max. 5,000min rpm

MAIN SPINDLE MOTOR

7.5kW (continuous)/11kW (15min.)

MAIN SPINDLE INDEXING ANGLE

C-axis control

THROUGH-SPINDLE HOLE DIAMETER

Ø52.5mm (2-1/16in)

CHUCKING TYPE

Hydraulic rotary cylinder

COLLET CHUCK TYPE

H-S22/DIN177E -

Sub Spindle

MAX. MACHINING DIAMETER

Ø51mm (2in.)

MAX. LENGTH FOR FRONT EJECTION

125mm (4-59/64in)

MAX. PARTS PROJECTION LENGTH

80mm (3-5/32in)

SUB SPINDLE SPEED

Max. 5,000min rpm

SUB SPINDLE MOTOR

7.5kW (continuous)/11kW (15min.)

SUB SPINDLE INDEXING ANGLE

C-axis control

THROUGH-SPINDLE HOLE DIAMETER

Ø52.5mm (2-1/16in)

CHUCKING TYPE

Hydraulic rotary cylinder

COLLET CHUCK TYPE

H-S22/DIN177E -

Path 1 Tool Post

TYPE

12-stationed turret

NUMBER OF TOOLS

Tool: 20mm (25/32in); Max. 2 tools/station

Sleeve: Max. 3 counterface sleeves/station

Power driven tool: Max. 2 tools/station

POWER DRIVEN TOOL

Spindle speed: Max. 6,000 min. rpm

Drive motor: 4.5kW (continuous) 7.5kW (5 min.)

Max. Drilling Capability: Ø16mm (5/8in)

Max. Tapping Capability: M12 xP1.75

Milling: Ø20mm (25/32in) -

Path 2 Tool Post

TYPE

12-stationed turret

NUMBER OF TOOLS

Tool: 20mm (25/32/in); Max. 2 tools/station

Sleeve: Max. 3 counterface sleeves/station

Power driven tool: Max. 2 tools/station

POWER DRIVEN TOOL

Spindle speed: Max. 6,000 min. rpm

Drive motor: 4.5kW (continuous) 7.5kW (5 min.)

Max. Drilling Capability: Ø16mm (5/8in)

Max. Tapping Capability: M12 xP1.75

Milling: Ø20mm (25/32in) -

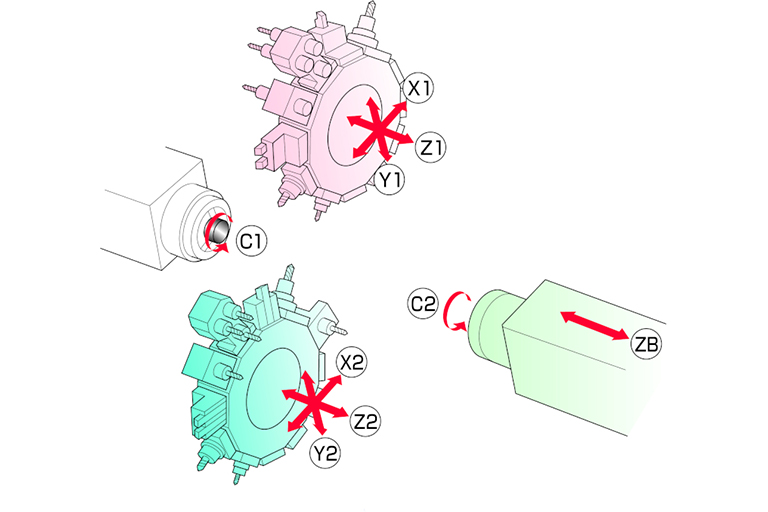

Rapid feed rate

X1, X2

20m/min

Y1, Y2

15m/min

Z1, Z2, Z3

40m/min

C1, C2 550 rpm -

Coolant tank

458ℓ

-

Coolant pump

1.5kW x 1 for each turret

0.4kW x 1 for each spindle -

Dimensions

2,800mm W x 2,070mm D x 2,130mm H

-

Weight

6,600kg

- Standard Machine Specifications

- Standard Accessories and Functions

- Optional Accessories and Functions

- CNC unit FANUC 32i-B

- Operation panel 15-inch color LCD display

- Pneumatic unit

- Hydraulic unit

- Automatic centralized lubrication unit

- Coolant level detector

- Door interlock system

- Cut-off tool breakage detection function (software)

- Cs contouring control (Main/Sub)

- Spindle clamp unit (Main/Sub)

- Spindle air purge system (Main/Sub)

- Pneumatic cylinder type product ejection system (with ejection detection system)

- Sub spindle mix blow system (Air & Coolant)

- Tool drive unit (Turret type tool post)

- Parts catcher

- Parts conveyor

- Work light

- Leakage breaker

- Coolant flow detector

- Water removal unit

- Cut-off tool breakage detection system (mechanical type)

- Main/Sub spindle upper air blow (for power chuck)

- Foot switch (Main/Sub chuck opening and closing)

- Tool setter

- Automatic bar feeder interface

- LAN/RS232C interface

- Hinge Belt Chip Conveyor

- Microfiltration Chip Conveyor

- Coolant Chiller

- Beacon

- High Pressure Coolant Pump

- Main/Sub chuck (to be selected from the tooling system)

- Main spindle inner tube

- Power Chuck for Main/Sub Spindle

- Collet Chuck for Main/Sub Spindle

- Coolant pump extension (2.5 MPa)

- Coolant unit (6.9MPa)

- Coolant unit signal cable

- Coolant system piping 6.9MPa

- Transformer CE marking version

- Transformer CE marking cable

- CE marking version

- Power Chuck Type - 6 inch