-

Max. Machining Diameter

ø20mm (25/32in)

-

Max. Headstock Stroke

G. B. TYPE

205mm (8in)

NON G. B. TYPE

Bar diameter × 2.5 (max. 50mm) (max. 1-31/32in) -

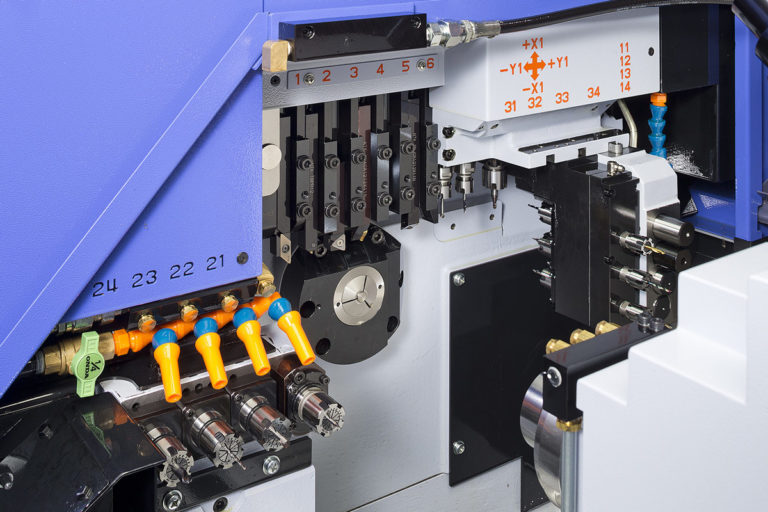

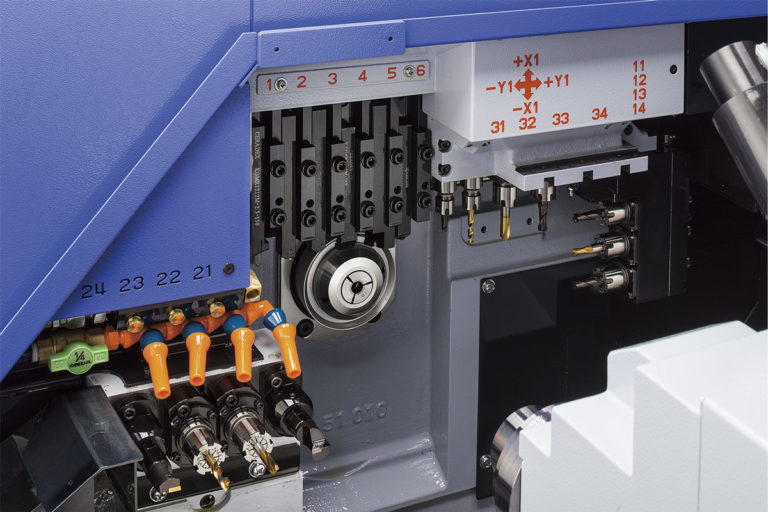

Number of Turning Tools

6 tools (ø12mm) / 7 tools (ø10mm)

-

4-Spindle Sleeve Holder

NUMBER OF TOOLS

Front: 4 tools / Rear : 4 tools

MAX. DRILLING CAPABILITY

ø12mm (1/2in)

MAX. TAPPING CAPABILITY

M10 × P1.5 -

Power-Driven Attachment - 4-SPINDLE CROSS DRILLING UNIT

NUMBER OF TOOLS

Cross Power Driven Att.: 4 tools (ER 16)

MAX. DRILLING CAPABILITY

ER 16: ø7mm(9/32in)

MAX. TAPPING CAPABILITY

ER 16: M6×P1.0

SPINDLE SPEED

ER 16: max.6,000min-1

DRIVE MOTOR

1.0kW (continuous) / 1.2kW (5min./30%ED) -

Power-Driven Attachment - 5-SPINDLE CROSS DRILLING UNIT

NUMBER OF TOOLS

Cross Power Driven Att.: 5 tools (ER 11)

MAX. DRILLING CAPABILITY

ER 11: ø5mm (3/16in)

MAX. TAPPING CAPABILITY

ER 11: M5×P0.8

SPINDLE SPEED

ER 11: max.10,000min-1

DRIVE MOTOR

1.0kW (continuous) / 1.2kW (5min./30%ED) -

Power-Driven Attachment - CARTRIDGE TYPE CROSS DRILLING UNIT

NUMBER OF TOOLS

Cross Power Driven Att. : 2 tools (ER 11)

Cartridge type: 3 Pos

MAX. DRILLING CAPABILITY

ER 16: 5-Spindle & 5-Spindle High Speed: ø7mm (9/32in)

ER 11: 5-Spindle: ø6mm; 5-Spindle High Speed: ø5mm

MAX. TAPPING CAPABILITY

ER 16: M6×P1.0

ER 11: M5×P0.8

SPINDLE SPEED

ER 16: max. 6,000 min-1

ER 11: 5-Spindle: max. 8,000 min-1; 5-Spindle High Speed: max. 10,000 min-1

DRIVE MOTOR

1.0kw (continuous) / 1.2kw (5min./30%ED) -

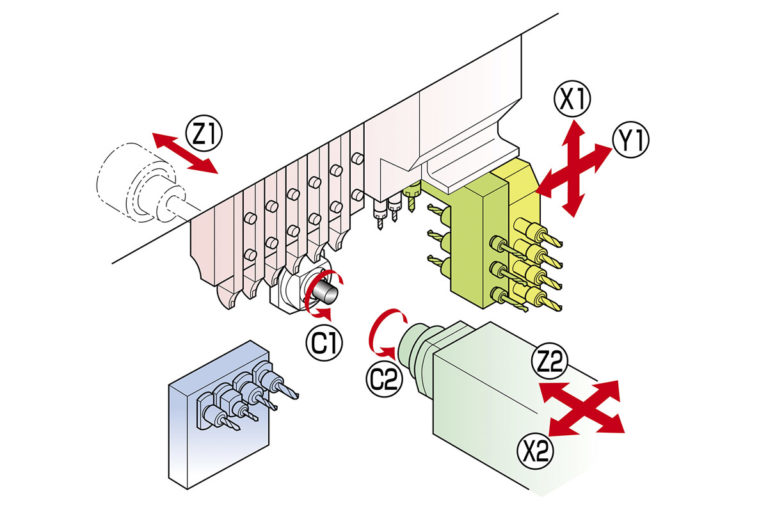

Rapid Feed Rate

35m/min (X1,Y1,Z1,X2,Z2)

-

Main Spindle Indexing Angle

C-axis control

-

Main Spindle Speed

max. 10,000min-1

-

Main Spindle Motor

2.2kw (continuous) / 3.7kw (10min./25%ED)

-

Coolant Tank Capacity

180ℓ

-

Dimensions (W × D × H)

2,070 × 1,177 × 1,760mm

Center Height - 1,060mm -

Weight

1,750kg

-

Power Consumption

3.7KVA

- Standard Machine Specifications

- Backworking Attachment Specifications

- Standard Accessories and Functions

- Optional Accessories and Functions

-

Max. Chucking Diameter

ø20mm (25/32in)

-

Max. Length For Front Ejection

80mm (3-5/32in)

-

Max. Parts Projection Length

30mm (1-3/16in)

-

Back 4-Spindle Unit

NUMBER OF TOOLS

4 tools

MAX. DRILLING CAPABILITY

Stationary Tool

ø8mm (5/16in)

Power-Driven Att.

ø6mm (15/64in)

MAX. TAPPING CAPABILITY

Stationary Tool

M6 × P1.0

Power-Driven Att.

M5 x P0.8 -

Power-Driven Att. Spindle Speed

Max. 8,000min-1

-

Power-Driven Att. Drive Motor

0.75kW

-

Sub Spindle Indexing Angle

C-axis control

-

Sub Spindle Speed

Max. 9,000min-1

-

Sub Spindle Motor

0.55kw (continuous) / 1.1kw (15min./40%ED)

- CNC unit Fanuc 0i-TD

- Operation panel 8.4” color LCD display

- Pneumatic unit

- Automatic centralized lubrication unit

- Coolant level detector

- Door interlock system

- Broken cutoff tool detector

- Parts ejection detector

- Drive unit for revolving guide bush

- Revolving guide bus unit

- Main/Sub collet

- C-axis control (Main/Sub)

- Spindle clamp unit (Main/Sub)

- Tool holder

- 4-Spindle cross drilling unit

- 4-Spindle sleeve holder

- Back 4-Spindle unit

- Air purge for revolving guide bush

- Air purge for main spindle

- Sub spindle air purge unit

- Sub spindle air blow unit

- Work light

- Leakage breaker

- Coolant flow detector

- Water removal unit

- Beacon

- Parts conveyor

- Parts receptacle in the machine

- Parts separator unit A

- Main spindle inner tube

- 5-spindle cross drilling unit

- Cartridge-type 5-spindle cross drilling unit

- Cartridge-type 5-spindle high-speed cross drilling unit

- Drive unit for power-driven attachment B

- Parts ejector (Air cylinder type)

- Parts ejector (Spring type)

- Parts ejector with guide tube

- Parts stopper unit

- Coolant unit (6.9MPa/2.5MPa)

- Coolant unit signal cable

- Coolant unit power cable

- Coolant valve

- Coolant pipings

- Automatic bar feeder interface

- Compliant with RS-232C interface

- Transformer

- Safety relay module version

- Transformer CE marking version

- Transformer CE marking specifications